Transporte neumático

Soplador de alta presión TRL 200

Pressure conveying systems are used to move grain from one place to another.

The TRL pneumatic conveying systems are suitable for wheat, barley, oats, rye, corn, canola, soybeans, and many other grains and granular products.

Pressure conveying systems require grain to be fed directly into a hopper above the injector or rotary valve. Kongskilde offers a variety of high-pressure blower models with different outputs to meet different system conveying needs.

Sopladores de succión SUC y SupraVac

Todos los sistemas SUC están diseñados para recoger el grano en el lado de succión y entregar el material en el lado de presión, por lo que no se necesita equipo de carga adicional. Nuestra amplia gama de sopladores de succión se adapta a las necesidades de todas las aplicaciones agrícolas. Desde instalaciones en fincas de baja capacidad hasta sistemas móviles de alta capacidad. Todos los sistemas aseguran limpieza de lote a lote y adquisición económica.

La capacidad eléctrica es de hasta 33 t/hora y la capacidad accionada por toma de fuerza es de hasta 120 t/hora. Para todas las configuraciones, Kongskilde ofrece una amplia gama de sistemas adicionales para una succión eficiente. Los diferentes tipos de cabezales y tuberías aseguran un manejo eficiente, cuidadoso con el material y convenientes para el operador.

Inyectores TF

Los inyectores TF 20/40/55 están diseñados para alimentar material de flujo libre (grano, finos, etc.) en una línea de transporte neumático.

Los inyectores TF están diseñados para usarse en combinación con los sopladores de alta presión TRL más pequeños de Kongskilde.

Válvulas Rotativas CAD/CAE

Las esclusas de aire/válvulas rotativas Kongskilde CAD se utilizan para introducir granos en los sistemas de transporte a presión para la entrega de granos a lo largo de la tubería.

Las válvulas rotativas Kongskilde CAE se utilizan en sistemas de transporte por aspiración para la descarga por gravedad de ciclones o unidades de filtración.

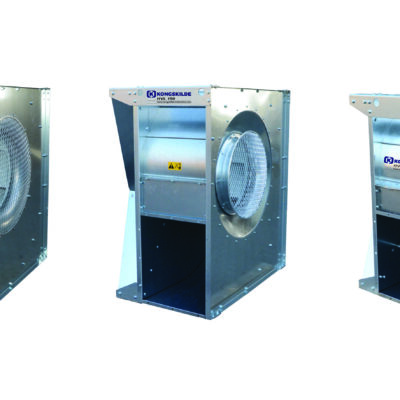

Soplador de aireación HVL

Kongskilde offers a wide range of high-volume, low-pressure blowers for efficient drying and storage ventilation of grain and other crops.

The blowers can also be used for exhaust and ventilation purposes in industrial installations.

Furthermore, the HVL blowers are an efficient air supply source to be used for ventilating steel silos independently of the air distribution system built into the silo bottom.

HVL Blowers – Efficient Drying and Storage Ventilation

Kongskilde offers a wide range of high-volume, low-pressure blowers, HVL 30, 55, 100, 150, 250, for drying and ventilating of grain, peas, grass seed, hay, beet, onions, and potatoes, and for drying and ventilation of larger grain and seed facilities we have the 400, 500, and 600 models.

The air flow rate of this blower type varies little with changes in the air pressure resistance, caused by different types of crops in silos, driers or on-floor storages. The HVL blowers are therefore also ideally suited for small-seed crops, having a higher resistance to the air flow, e.g. rape seed, clover, and mustard.

Owing to the very low temperature rise the HVL blowers are also suitable for ventilation and cooling of crops.

In industrial installations the HVL blower may be used for exhaust and ventilation purposes.

The HVL blowers can be installed in parallel – two smaller HVL blowers set up in parallel offer some advantages. This type of installation gives better flexibility when drying only partially filled systems. Furthermore, the starting ampere of each smaller blower is less demanding on the electrical installation.

Benefits

- Ideal for all sizes of installations.

- Made of galvanized steel, suitable for outdoor installation.

- Rotors with backward curved blades, carefully balanced and thus reducing noise and vibrations to a minimum.

- Sturdy construction.

- Direct driven motors, reducing service time and costs.

- HVL 30 – 250 for horizontal or vertical installation without the need for extra parts.

- Vibration dampers available as optional for HVL 30 – 250.

- Rain cover for outdoor installation available as optional.

Ventilador aspirador FRL (Only available in North America)

The FRL 15 Aspirator Fan is an effective, economical way to give your grain an air wash and remove any light, unwanted foreign materials like dust and bees’ wings (red dog). Plus, its adaptability makes it a great addition to your operation. Add it to the discharge on grain dryers or place it at the head or boot of grain elevator legs or conveyors and let it clean away!

Improve Grain Quality and Reduce Cost

The FRL Aspirator Fan is an effective, economical way to give your grain an air wash and remove any light, unwanted foreign materials like dust and bees’ wings (red dog). Plus, its adaptability makes it a great addition to your operation. It can be added to the discharge on grain dryers or placed at the head or boot of grain elevator legs or conveyors.

4 Good Reasons to Clean Your Grain

Improves grain quality

By removing unwanted materials, you improve your FM counts and reduce dockage at the elevator.

Improves aeration

Another great benefit is that with the fines removed, air circulation is also improved in storage facilities without overtaxing aeration fans. Goodbye hot spots and spoilage!

Eliminates plugging of e.g. bees’ wings

Bees’ wings are known for plugging up systems. By removing them from your grain, you can add downspouts to legs without worrying about clogging and downtime.

Prolongs equipment life

The cleaner you keep your equipment, the longer it lasts. Removing bees’ wings and other contaminants to a bin keeps your processing area clean and working at peak performance